Case #004 - When FC Transfer Becomes the Problem (Not the Inventory)

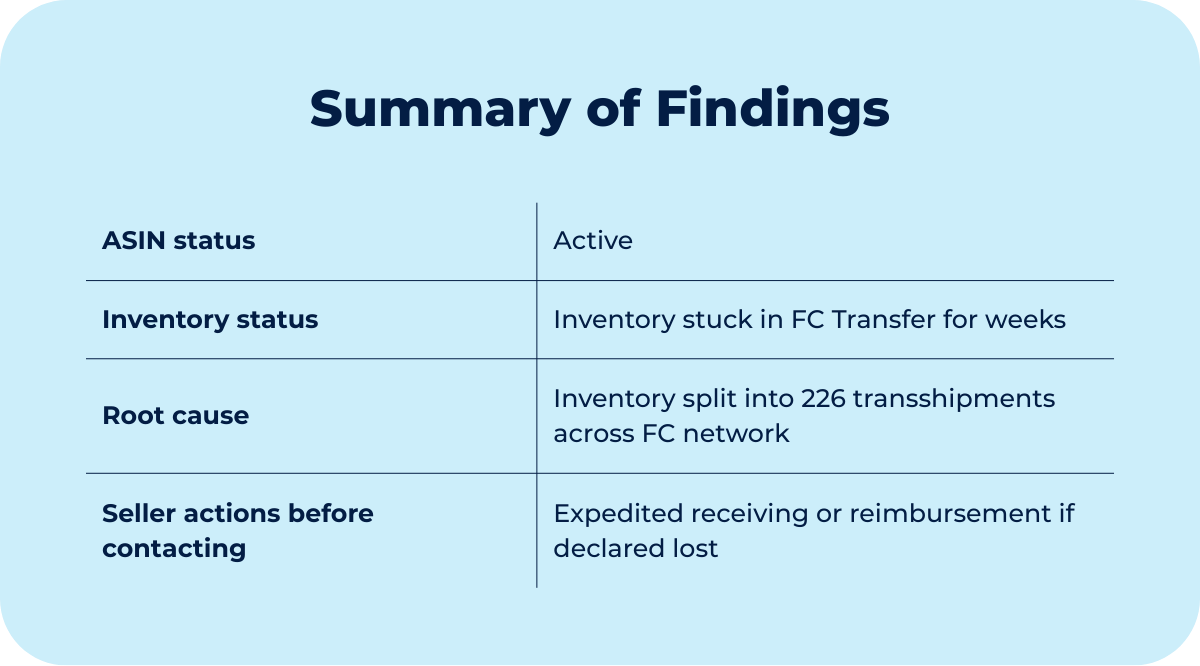

Inventory didn’t go missing. It was fragmented into 226 micro-shipments, and the system treated it as low-priority freight.

Context

When inventory is in FBA, but you can sell it

This case didn’t begin with a lost shipment, stranded inventory, or an inbound discrepancy. It began with something most experienced sellers have seen at least once: inventory that arrives at Amazon, but never seems to become available, a.k.a stuck in FC Transfer.

A popular ASIN had just been replenished into FBA. The shipment closed normally, the units were checked in, and then everything stopped. For days (and then weeks), the status stayed locked in FC Transfer. The seller kept refreshing the page, watching nothing change, while performance slowly deteriorated in the background.

No Prime 1–2 day delivery.

No sellable inventory.

No clear explanation inside Seller Central.

And the pressure was growing. The seller already had another inbound of more than 1,000 units planned for that same week, but couldn’t tell whether the current inventory problem represented a delay, a system error, or something more serious.

Sending more stock without understanding what was wrong risked over-allocation of capital, higher storage exposure, and the possibility of duplicating the problem again.

What actually mattered wasn’t the label “FC Transfer.” It was what was happening to the units while they were in that status.

This is where many operators fall into traps. They assume inventory is “just transferring” and simply wait, or they open general cases asking Seller Support to “expedite FC transfer,” hoping someone in the background will flip a switch. Instead, this case required a different question: Instead of asking why it’s delayed, ask: How is Amazon moving my inventory from FC to FC?

That shift in thinking changed everything that followed.

Diagnostic

Why did everything look “normal” in Seller Central, and still wasn’t right

Once we obtained backend visibility into the inventory records, the situation stopped being mysterious.

The units were not sitting idle or missing. Instead, they were constantly moving, just not in a way that was helpful to the seller.

Amazon had broken the replenishment into 226 separate transshipments scattered across the fulfillment network. Each represented a very small packet of units being moved from one FC to another to rebalance regional inventory pools.

And there is a simple but important rule for moving inventory to understand all this.

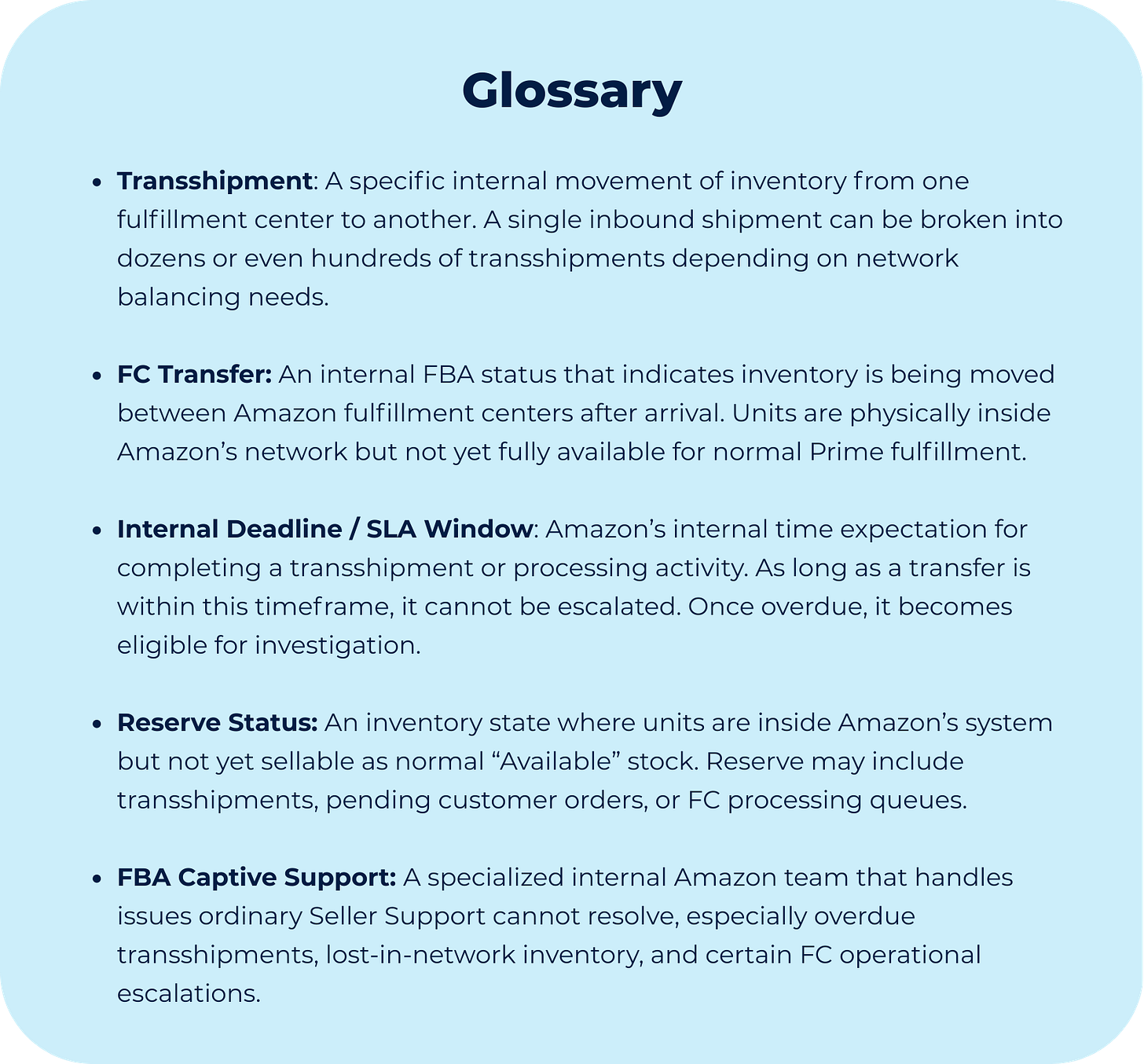

If a transfer is still within the internal Amazon deadline window, it cannot be escalated, even if it already feels unreasonably slow from the seller’s perspective. Once it crosses that deadline, it becomes eligible for investigation, and only then can Amazon decide whether to expedite the movement or reimburse the inventory.

Many of the transfers associated with this ASIN were still within that time window. However, 74 of them were already overdue by several days, which moved this situation out of routine processing and into exception handling.

Making this the diagnostic conclusion:

The inventory delay was driven by extreme fragmentation across internal transfers.

Most units were still moving normally within Amazon’s network.

A defined subset qualified for escalation due to missed internal deadlines.

And the situation could not be resolved through standard Seller Support paths.

Understanding this determined everything that followed.

Thought Process

How to think about FC Transfer delays without fighting the system

Most sellers approach FC Transfer issues as a visibility problem: inventory isn’t “Available,” Prime shipping isn’t active, so something must be wrong. The instinct is to escalate broadly and ask Seller Support to “fix” the status.

That approach almost always fails.

So the first question was not, “How do we speed this up?“

but, what processes can Amazon actually expedite or break up?

From experience, we know Amazon draws a hard line between:

Inventory that is still within internal expectations (no intervention possible)

Inventory that has exceeded internal thresholds (limited intervention possible)

That distinction is invisible in Seller Central, but it governs everything.

Instead of repeatedly asking for availability, we mapped the problem to Amazon’s internal rules. Transshipments that are still within their “Receive By” window are effectively untouchable. No escalation, no justification, no urgency will move them faster. Trying to push those only wastes time and credibility.

The only actionable path was to isolate which transfers had crossed Amazon’s own deadlines, because those are the only ones that trigger internal accountability.

This reframing changed the strategy entirely. The objective was no longer to override Amazon’s logistics model. It was to align the request with a condition Amazon already recognizes as an exception.

Once the problem was narrowed that way, the solution path became clear: stop treating the delay as a single issue and start treating it as a portfolio of internal movements, each with a different status and different rules.

That’s how you move from frustration to resolution inside Amazon: not by pushing against the system, but by understanding exactly where the system allows pressure to be applied.